Advanced Variable Frequency Drive Technology

The

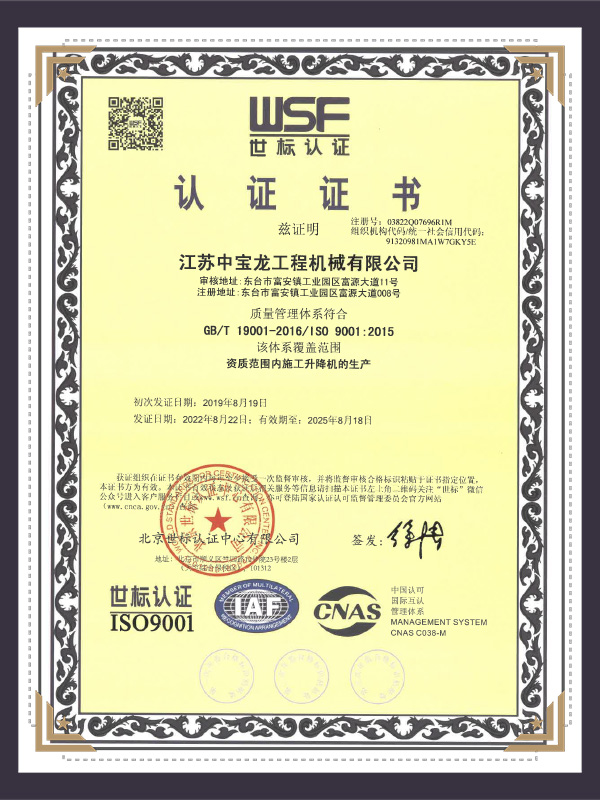

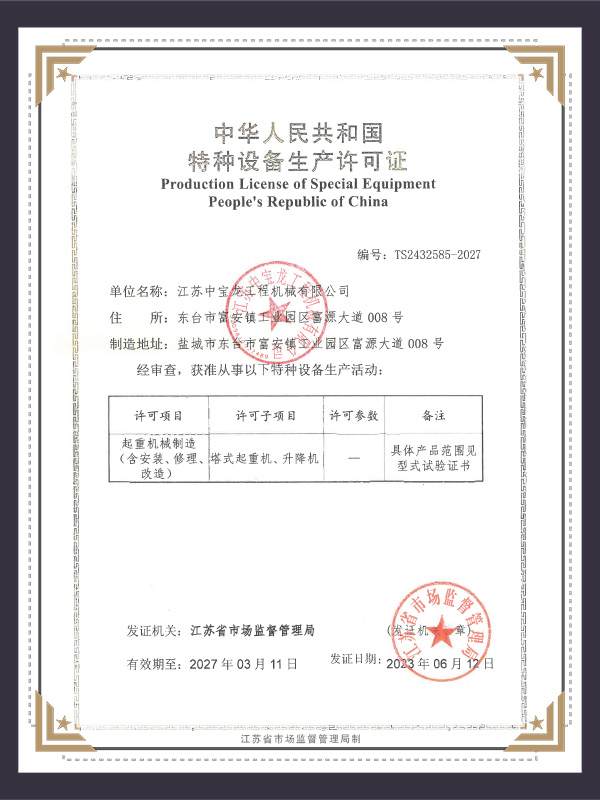

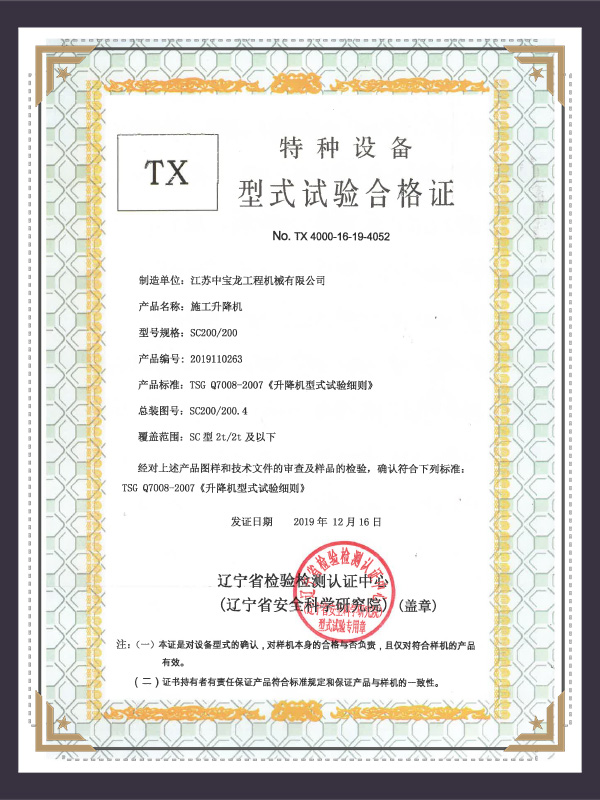

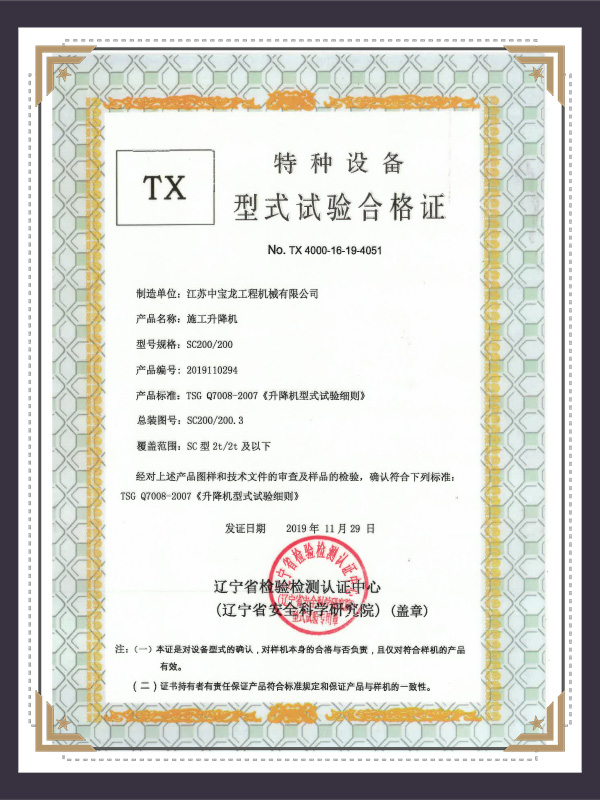

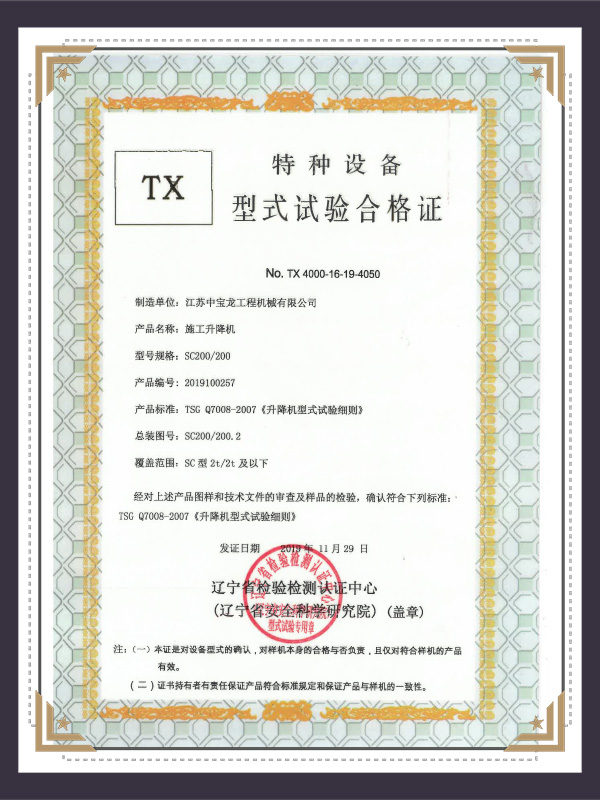

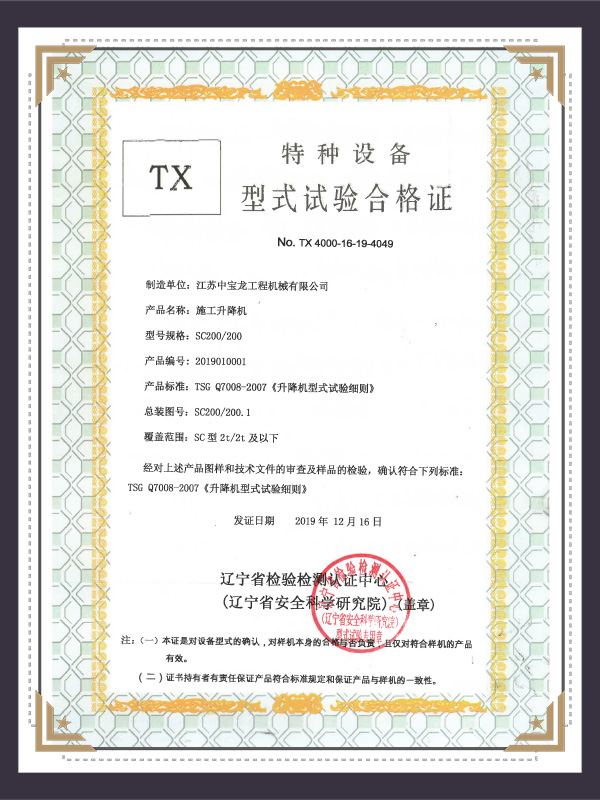

SC200/200 Variable Frequency Low Speed Construction Hoist integrates sophisticated variable frequency drive (VFD) technology, which represents a significant advancement in the realm of construction lifting equipment. This technology is pivotal in optimizing both the efficiency and operational capabilities of the hoist, setting a new benchmark in performance and control. Jiangsu Zhongbaolong Engineering Machinery Co., Ltd., a leading manufacturer and supplier in the construction machinery industry, incorporates this state-of-the-art technology into the SC200/200 to deliver superior lifting solutions.

a)Comprehensive Overview of Variable Frequency Drive Technology: Variable frequency drive technology, also known as variable speed drive (VSD) or adjustable speed drive (ASD), is a method used to regulate the speed and torque of an electric motor by varying the frequency and voltage supplied to it. Unlike traditional systems that operate at a constant speed, VFDs allow for precise control over the motor’s speed, providing a range of operational speeds suited to different lifting requirements. This level of control is especially critical in construction environments where variable loads and speeds are common. Jiangsu Zhongbaolong Engineering Machinery Co., Ltd. harnesses this technology to enhance the SC200/200 hoist's performance and adaptability, ensuring it meets the diverse needs of modern construction projects.

b)Precision and Control: One of the standout features of the VFD technology in the SC200/200 hoist is its ability to offer unparalleled precision and control. The VFD system allows the hoist to adjust its lifting speed smoothly and gradually, which is essential for tasks requiring accurate load positioning. For example, in the construction of high-rise buildings where materials need to be lifted to specific floors with exactitude, the SC200/200 can fine-tune its speed to accommodate the precise requirements of the task. This capability minimizes the risk of abrupt movements that could lead to accidents or damage to the materials being lifted, thereby enhancing overall safety and efficiency on the construction site.

c)Energy Efficiency and Cost Savings: The integration of VFD technology in the SC200/200 hoist also translates into significant energy efficiency and cost savings. Traditional hoists often operate at a fixed speed, resulting in unnecessary energy consumption even when full power is not required. In contrast, the VFD system adjusts the motor speed according to the load demand, optimizing energy use and reducing wastage. This efficiency not only lowers operational costs but also contributes to environmental sustainability by reducing the overall carbon footprint of the hoist's operation. Jiangsu Zhongbaolong Engineering Machinery Co., Ltd. is committed to producing equipment that supports both economic and environmental goals, and the SC200/200 hoist's VFD technology exemplifies this commitment.

d)Durability and Reduced Maintenance: Another significant advantage of the VFD technology is its impact on the durability and maintenance requirements of the SC200/200 hoist. By enabling smooth starts and stops, the VFD system reduces mechanical stress on critical components such as gears, bearings, and motors. This reduction in mechanical strain leads to fewer maintenance needs and extends the lifespan of the equipment. The robust design and reliable performance of the SC200/200 hoist are a direct result of Jiangsu Zhongbaolong Engineering Machinery Co., Ltd.'s focus on integrating advanced technologies that enhance durability and reduce total cost of ownership.

e)Enhanced Safety Features: Safety is a paramount concern in construction operations, and VFD technology plays a crucial role in enhancing the safety features of the SC200/200 hoist. The VFD system provides precise control over the hoist's speed and movement, which is essential for minimizing the risk of accidents caused by sudden or unpredictable motions. The VFD technology allows for the implementation of advanced safety protocols and alarms that alert operators to potential issues such as overload conditions or system faults. This proactive approach to safety aligns with Jiangsu Zhongbaolong Engineering Machinery Co., Ltd.'s commitment to providing equipment that meets the highest safety standards.